What is the Last Planner System®

“Last Planner® can be understood as a mechanism for transforming what SHOULD be

done into what CAN be done, thus forming an inventory of ready work, from which

Weekly Work Plans can be formed, including assignments on Weekly Work Plans as a

commitment by the Last Planners (foremen, squad bosses) to what they actually WILL do.”

– Glenn Ballard

Why use The Last Planner® System?

Proven benefits of Last Planner include shorter schedules, increased productivity, greater process transparency and improved site organization, better collaboration, communication and understanding, more stable workflow and matching of crew resources, speedier RFI replies and submittal approvals. The Last Planner System is the gateway to Lean behaviors and addresses key components not working in Critical Path Method scheduling including:

• Little trade foreman input and buy-in.

• Lack of a visually understandable plan because information is buried in hard-to-read bar

charts or Excel spreadsheets.

• Lack of clear tracking of the plan on a day-to-day and week-to-week basis because the work is disconnected from the CPM schedule.

What is the Last Planner System?

A system used for production planning control (scheduling) that was first used by the developers Glenn

Ballard and Greg Howell in 1992 for use on projects to improve workflow, plan reliability and the

predictability of work. The basic premise is those who do the work plan the work and make

commitments to complete work (reliable promises) to other members of the team.

Last Planner focuses on five key principles:

- Detailed planning and reliable commitments are made as the tasks get close (within 2 weeks)

- Those who do the work, plan the work. The “Last Planners” (trade foremen, designers, suppliers etc.) often plan with a combined experience of 300+ years.

- Identify constraints of planned tasks and removed them in advance of the work.

- Reliable promises are made and kept by the Last Planners.

- Reasons for missed commitments are used to develop organizational learning capability and create a culture of continuous improvement.

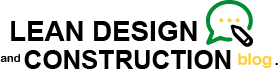

There are four elements of the Last Planner (Should, Can, Will, and Did):

“There are 5 connected conversations listed below. These really encompass the four elements: Should, Can, Will, and Did. And they exist on 3 levels: Milestone (30,000’), Phase Pull (10,000’) and “Weekly Work Planning (Ground Level) which encompasses items 3-5.”

- Master Scheduling (Should): Set milestones and strategy of what you SHOULD do, while identifying long lead items.

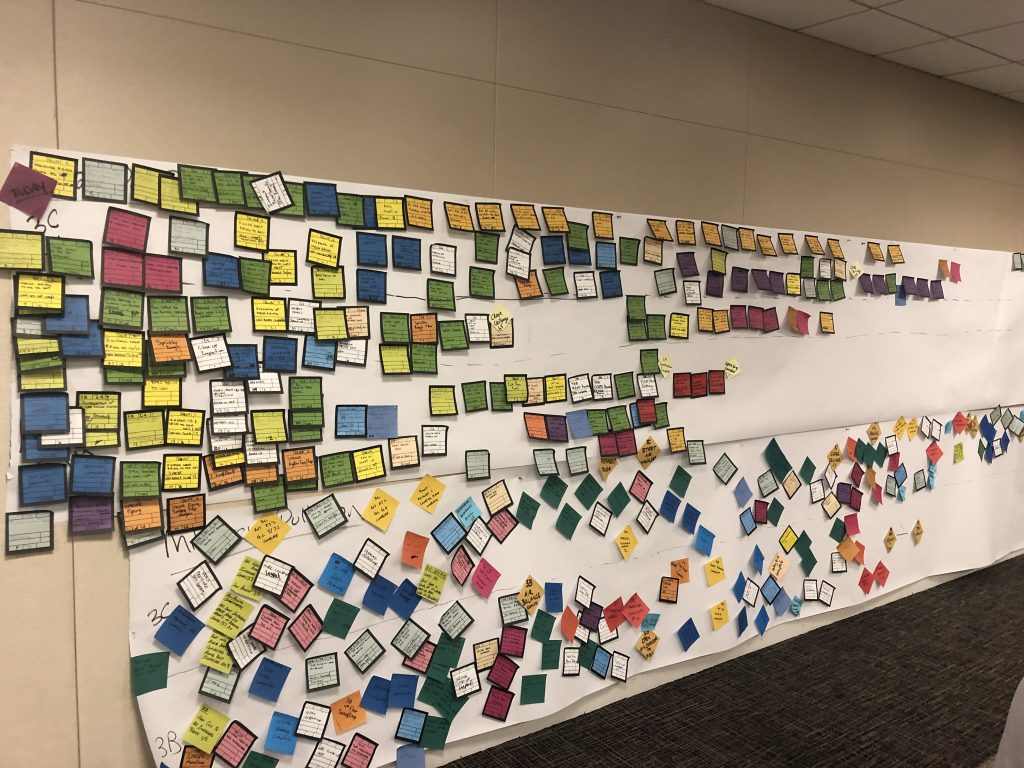

- Phase “Pull” planning (Should/Can): Specify the handoffs, identify operational conflicts and uses Post-Its ® , to start to identify what you CAN do from what you SHOULD do.

- Make Work Ready Planning (Can): Look-ahead planning to assure that work is made ready, so it CAN be done.

- Weekly Work Planning (Will): Make reliable commitments for the work that you WILL do.

- Learning (Did): Measure “percent of promises complete”. (PPC), dive deep into reasons for failure, and develop/implement lessons learned.

Other key components of the Last Planner:

• The Last Planners attend “Daily huddles” at a set time every day for 15 minutes. The superintendent will lead the short huddles and look at the previous day’s tags to see the percent of promises complete (PPC), reschedule any works (if necessary) and secure promises from the Last Planners for the current working day.

• First Run Studies (FRS) are basically mock- up trials of how certain aspects of work will be performed in advance of the work actually taking place. This can help refine the sequence of work and how it should flow from one specialist (trade) to the other.