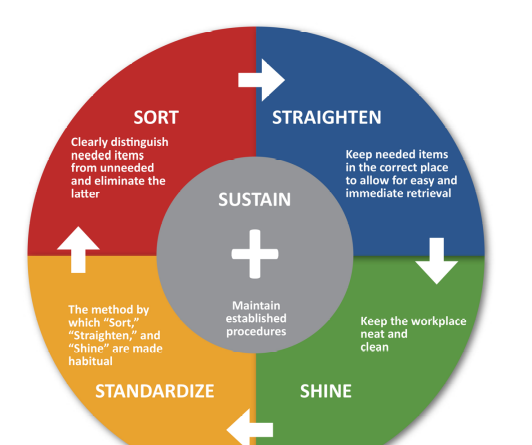

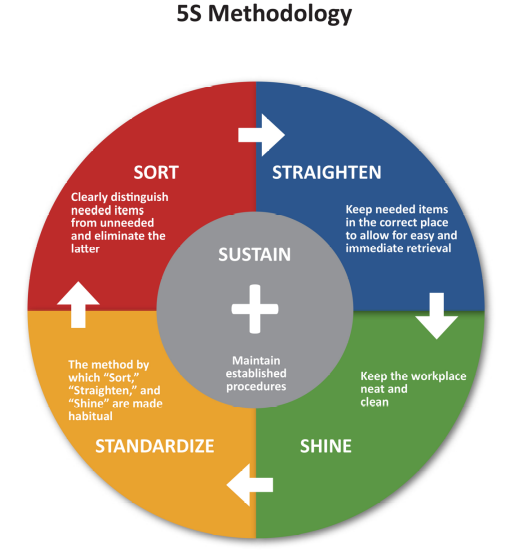

Introduction to 5S

5S is a system for organizing where your work is done, whether that is on a construction site, in an office, or at your workspace. So, is it just cleaning and organizing? No! It’s about learning to see and remove the waste in our everyday work so we can perform more productively, safely, and with less stress.

There are 5 steps to 5-S, all beginning with “S”:

Sort– What tools, equipment, and materials are needed to the do the job and what can be removed? Sort the necessary from the unnecessary! Consider:

Who uses this item and how often?For unnecessary items, can someone else use it, or should it be stored, trashed, or recycled?

Straighten/Set in Order– Now that you have identified what is necessary to actually perform the work, where is the optimal place for each item? A place for everything, and everything in its place! Consider:

Where will you put items needed most often so they are quick and easy to find?Which items are related and should be grouped together to minimize excess searching, picking, and movement?Do you need labels, new bins, or other organization to help ensure items can find their “home” once removed?Do anything you’ve made better need to change based upon who else may need these items?

Shine– With everything in its place how does the workspace look? Clean, sweep, and inspect the workplace on a regular basis to make it safer and more pleasing to work in. Consider:

Could anyone not familiar with the area quickly and easily detect a problem? While cleaning, do you notice anything that needs to be Sorted or Set in Order?

Standardize – How will you ensure that the first 3Ss are followed? Consider:

How will you change your workday to make it part of your daily routine? What procedures and schedules are needed to support your 5S efforts? What checklists or visual controls will help keep standards top of mind?

Sustain – How will you ensure the 5S process continues to be followed? Consider: How will you conduct training?

How often will you verify that your standards are being followed?How will you improve your 5S process and recognize workers for doing so?

That’s 5S. And it helps us stabilize our workplace (field or office), which is essential to stabilizing our systems, which is essential to improving them.