Benefits Of Using The Last Planner System® Fact Sheet

“Our construction industry suffers from a lack of collaboration due in part to our project teams’ inability to communicate in an effective manner. The Last Planner System® promotes healthy communication and it works!”

– Terry Brickman, Vice President Quality Management & Lean Transformation, PCL Construction Enterprises

Variability of labor cost due to productivity and schedule delays is the most likely factor to cause project

cost overruns. A productivity study from Professor Paul Teicholz from Stanford University in 2013

shows how construction labor productivity has declined 0.32% annually from 1964 through 2012 and

the gap in productivity between construction and other sectors of the economy has doubled in the last

decade. Construction project costs typically are split evenly 50/50 between labor and materials. A study

by the Construction Industry Institute in 2004 observed labor productivity of construction crews

ranging from 8 to 25%. Other case studies have observed typical labor of productivity at 30 to 35%. It

follows that if half of the cost of a project is tied to labor and productivity is less than 35%, then 30% ir

more of the project value may be tied to non-productive activities resulting in lost profit and higher

costs to the owner.

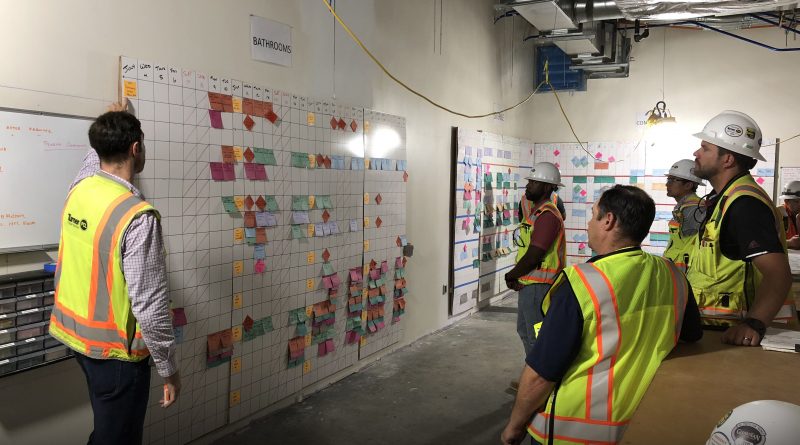

The Last Planner System (LPS®) of production planning developed by Greg Howell and Glenn

Ballard in the 1990s has been growing in use over the past 15 years on projects all over the world.

When used properly LPS can dramatically improve productivity and contribute to significantly better

project performance. It does this by engaging those that will actually be conducting the daily planning

of the work on the job, the superintendents and foremen or Last Planners, through a series of

interconnected commitments in a highly visual environment. Howell and Ballard learned through their

search that on average 54% of what was planned on a weekly basis by superintendents was actually

completed. Using LPS, this completion rate moves into the 80 to 90% range weekly for

high-performing teams.

A Brazilian LPS study involving 16 companies in 2010 reported that 95.5% of the participants were

more satisfied with using LPS over previous planning and control techniques such as Critical Path

Method (CPM). The interviewees’ perceptions of the effects of LPS versus traditional methods are

displayed below.

Reducing project schedules and cost through Last Planner System

- The $645 million California Department of Corrections and Rehabilitation California Healthcare Facility was delivered in 2012, 5 weeks early using LPS. The project only started using Last Planner System 22 weeks before the completion deadline in order to double daily work in-place from $1.5 million/day to $3 million/day to meet the finish date.

- The Kaiser Permanente Oakland Hospital Replacement Project finished 3 months early and won ENR Best Health Care project in California in 2014 using LPS.

- John Wayne Airpot, Terminal 3 in Santa Ana (CA) and the £4.5 billion UK Heathrow Terminal 5 project were both delivered on time using the Last Planner System.

Common Takeaways from Last Planners

General conditions account for a significant portion of every project budget ranging from $2,000 a

day in smaller projects to $50,000 a day on larger projects. Costs are incurred for field staff including

superintendents, project engineers and field administrative support as well as trailers; utilities (water,

power, communications); site security; office supplies; insurance; trade partners and owner

representative salaries and expenses, equipment & machinery rentals, and financing. These are all

direct savings from finishing on time or early. The earlier the finish, the greater the savings.

Other studies indicate projects using the Last Planner System have many other benefits including:

- In a Brazilian LPS study in 2010 involving 16 companies greater planning process transparency and task visualization (26.2%) and improved site organisation (23.1%) resulted in improvements in team organization and site safety.

- Site workers become more productive. Bricklayers increased their productivity from 108 sq. ft./worker/day to 178 sq. ft./worker/day while also using load leveling and material visualization tools.

- Better collaboration, communication and understanding happens as foremen and superintendents become more engaged. Teams become more accountable as they commit to plans and decisions that they are making in front of their partners. They are now looking out for each other. “LPS opens up the lines of communication” and “Why tell one subcontractor what another is doing, when they can do it themselves.”

- Reduced buffer time in schedules or “sandbagging” by trades as trust builds and reliable commitments are met.

- Good process for trust, camaraderie and communication building, understanding other team

members work and achieving buy-in to plan. Transparency helps to identify constraints and

interdependencies of tasks. - More stable workflow and better matching of available labor force and other resources increased

plan reliability and decreased the number of emergency requests for resources and

work-in-progress. - Root causes of issues are addressed in a timely manner with development of effective

countermeasures. - Reduced risk of liquidated damages, associated legal costs and lost capacity to do work for other

customers. - Reduced risk of liquidated damages, associated legal costs and lost capacity to do work for other customers. Speedier RFI replies and submittal approvals by involving the design team in LPS increases reliable work flow and reduces delays.

- Punch lists and rework are significantly reduced because the work is accepted or rejected at the handoff between trades. Therefore, defects do not continue down the line.

- Last Planner System is the gateway to Lean behavior regarding collaboration; identifying value and waste; participation, communication and transparency; trust building, reliable promising and clear commitments; goal-driven behaviors; systemic thinking and root cause analysis; learning and continuous improvement; short and long term planning; and promoting flow, small batching and a visual workplace.

Common Takeaways from Last Planners

- Good team coordination and cooperation.

- Last Planner® success is dependent on teamwork and solid commitments being kept.

- Good way to keep everyone accountable and understand each other’s scope of work.

- The visible aspect of the pull planning wall and weekly work plans are really helpful.

- Good to meet and see who all the project players are before commencing on site.

- Standing up and working at the wall kept the attendees focused.

- LPS can benefit the whole project especially in design/build, design/assist and IPD.

- Reverse planning (Pull Planning) can more fully identify constraints.

“Without a mid-course correction from conventional CPM look- ahead schedule management to Last Planner, it would not have been possible to complete the project early. And we certainly would not have produced a $60M month, the largest on a State project in history.”

– Mike Ricker, Vice President, Clark Construction on the California Health Care

Facility, California Department of Corrections and Rehabilitation, Project in Stockton, CA.