What is Lean Construction?

The term ”Lean” came from John Krafcik who was a graduate student at MIT, working for Lean Enterprise Institute founder Jim Womack on the research for the book The Machine That Changed the World to describe the processes of the Toyota Production System, whose twin pillars of Respect for People and Continuous Improvement seek to maximize Value (as defined by the Customer) and reduce Waste.

Lean thinking, or this idea that we try to increasingly maximize value while increasingly reduce waste in our processes and organizations, has been the natural successor to the W. Edwards Demmings’ Total Quality Movement in industrial processes. It has resulted in Lean Manufacturing (which is nearly all manufacturing globally), promulgated by the Lean Enterprise Institute; Lean Six Sigma, which seeks to drive defects out of complicated manufacturing processes; and Lean Healthcare which re-focuses and re-designs the way healthcare is delivered by maximizing value to patients rather than maximizing healthcare resources. Beginning in the early 1990’s (coinciding with the founding of the International Group for Lean Construction and Ballard and Howell’s early work) these earlier and continuing Lean practices have been broadened to every type of vertical and horizontal design and construction which increasingly embrace Lean culture, practices and tools.

Why Lean Design and Construction?

Implementation of Lean Thinking in design and construction has revolutionized the way projects are conceived, designed, planned, implemented, commissioned, and operated. It has taken Lean thinking in production and delivery and reformatted it for how the built environment is designed and delivered, viewing projects as production systems which maximize flow.

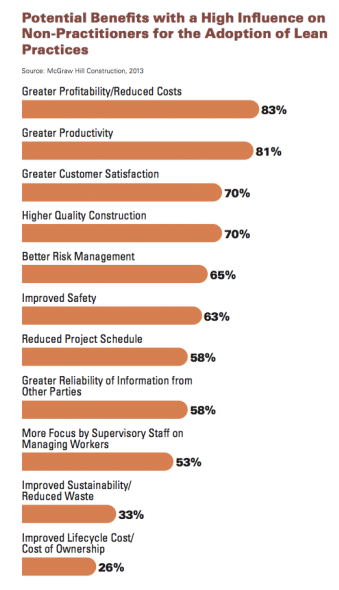

In 2013 Dassault Systems and Lean Construction Institute partnered with McGraw Hill to conduct a seminal study which documented the potential benefits of lean implementation. That study (see graphic) reported that “[a]ll the experts interviewed have realized significant benefits by using Lean construction techniques . . ..”